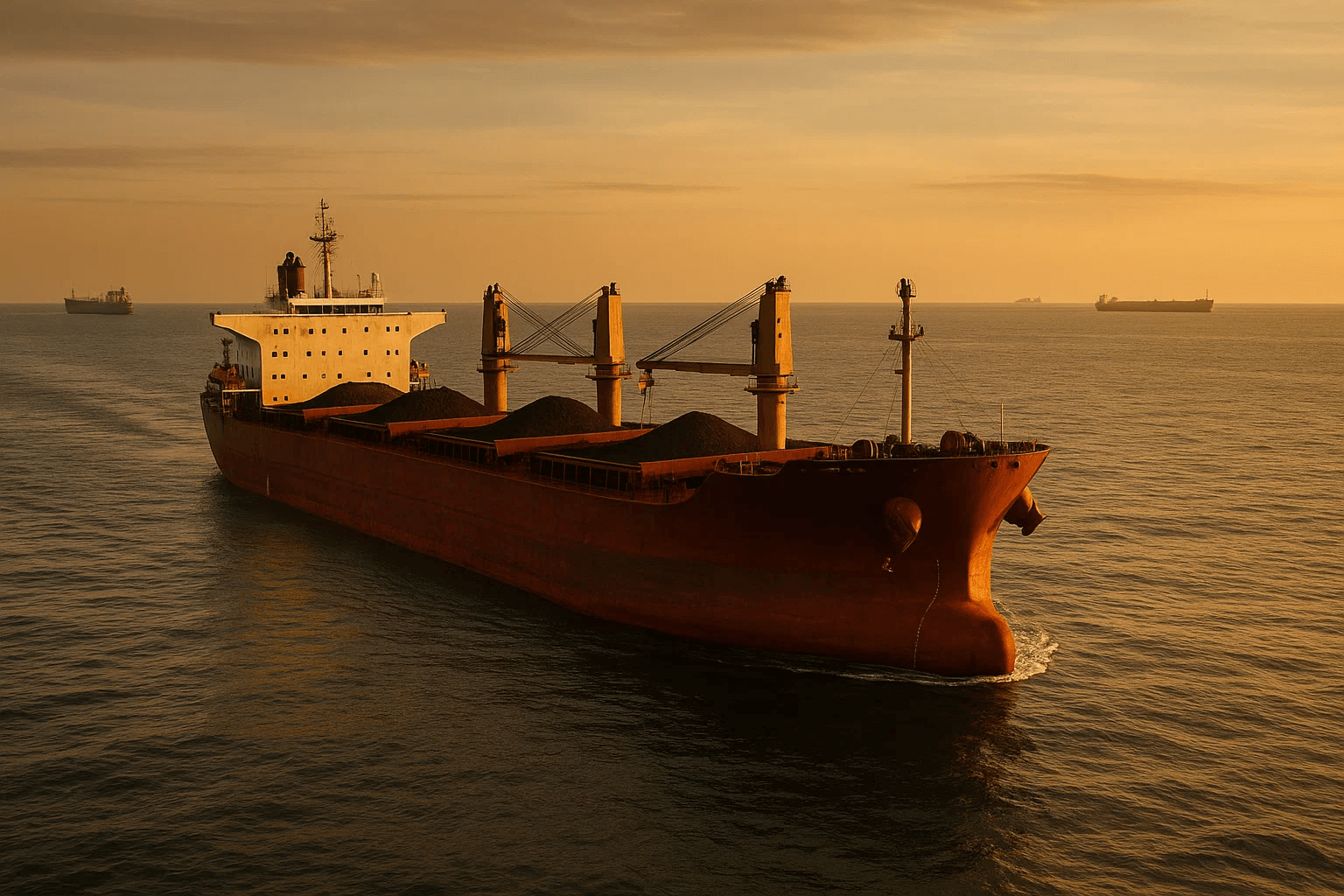

Maritime transport is considered among the most polluting sectors worldwide. In fact, greenhouse gas emissions account for 2.89% of global emissions, according to the latest estimates of the International Maritime Organisation (IMO). International ship traffic is constantly growing. Mitigation measures are therefore necessary as a challenge to the sustainability of the shipping industry and port infrastructure. One of the most hotly debated topics worldwide is cold ironing. This is a measure that can eliminate local pollution in the port area, which is often integrated with the urban fabric. Cold ironing is a proposed solution to reduce greenhouse emissions from ships docking in port.

To get an idea of the pollution produced by ships, one need only think that a cruise ship docked at a quay in ten hours produces CO2 emissions equivalent to those of 25 medium-sized cars in one year. The energy consumption of a cruise ship is equivalent to that of a city with 80,000 inhabitants. Thus, maritime transport is responsible for the emission of harmful gases into the atmosphere, which, in addition to carbon dioxide, also include sulphur and nitrogen oxides, particulate matter, carbon monoxide and volatile organic compounds.

Ships that are considered to be the most polluting are therefore those that are stationary or performing manoeuvring operations. The emissions produced in these cases are estimated to be 80 per cent of total port emissions. The mooring emissions of the port of Rotterdam are 640 thousand tonnes of CO2 per year, while the port of Antwerp produces about 351 thousand tonnes per year. In Italy, ports along the coast are among the most polluting in Europe, with 1165 thousand tonnes per year. The largest contribution is made by the port of Genoa. Added to this is the fact that 90% of European ports are located close to urban areas.

Barriers to overcome

Cold Ironing is not yet a mature technology due to a number of operational difficulties. The power grid must be designed to meet the electrical needs of ships, which can have very different characteristics depending on the type. There are also a number of bureaucratic hurdles, because power supply standards have to be consistent worldwide and ships have to be rethought to adapt to this power supply system. Cold Ironing is still a technology that does not take off because of the lack of a defined regulatory framework and because of the high investment required.

The Cold Ironing Challenge

Awareness of the need to make maritime transport sustainable is a starting point for the spread of technologies such as cold ironing. In fact, the European Green Deal leaves room for the decarbonisation of transport by ship. This is why the electrification of ports is progressing thanks to funding that can overcome some of the barriers that currently hinder its spread. Moreover, for the time being, there is a lack of adequate push by port authorities for the implementation of electrical infrastructure. This situation can partly be explained by the low demand for the service from ship owners.

Recently, the European Parliament finally adopted new rules on alternative fuel infrastructure. In order to significantly reduce air pollution in ports, from 2030 container ships and passenger vessels will be required to connect to shore power for all their electricity needs when berthed on the quays of major EU ports. Once the Council formally adopts the law, the sustainable maritime fuel standards will apply from 1 January 2025.

#SlothSea #Shipping #Coldironing #Environment #Ecogreen #energytransition