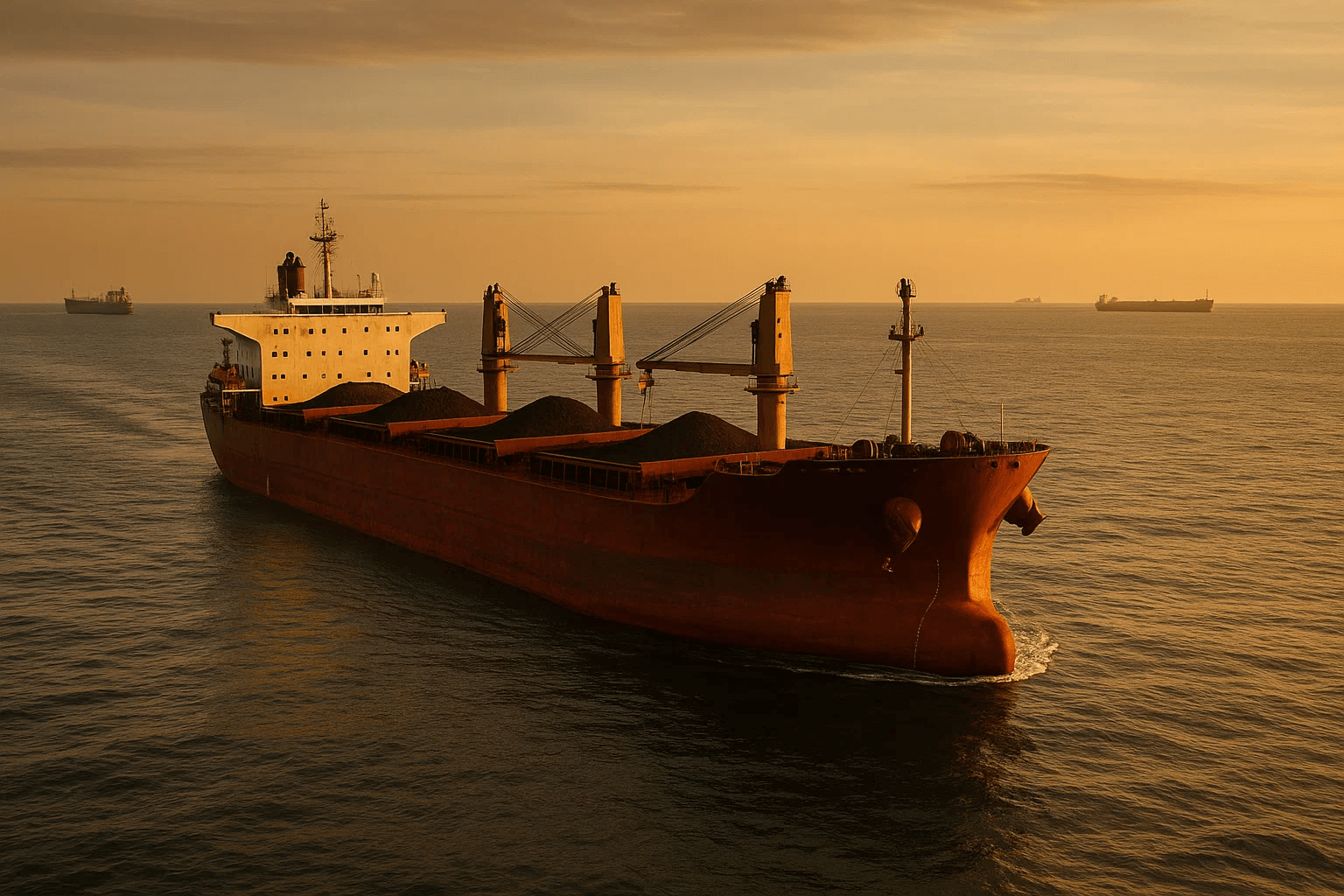

In recent years, several Italian public entities have started programs to modernize their fleets, supported by state and EU funds and promoted by institutions such as the “Ministero delle Infrastrutture e dei Trasporti”, the “Guardia Costiera”, and the “Guardia di Finanza”. These initiatives aim at shared objectives, including improved operational safety, compliance with new environmental and regulatory standards, and greater efficiency of vessels in essential services. Measures under the National Recovery and Resilience Plan (NRRP) for “green” fleet renewal and agreements for modernizing local maritime public transport, including both new builds and refits, have also contributed to this activity. Despite differences in timing and approach across sectors, the industry has seen renewed momentum in vessel replacement and construction compared to previous years.

A closer look at public tenders reveals a recurring pattern. Many allow subcontracting or collaboration with foreign operators, fully aligned with EU procurement rules and free market principles. In practice, this often results in a division of work where a significant portion of construction or key components is carried out abroad, typically in lower-cost production contexts.

The issue is not a confrontation between Italian and foreign shipyards, nor a critique of competition itself. The involvement of foreign operators is consistent with market logic, provided it is explicitly allowed in the tender and all technical, environmental, and social requirements are met. The key consideration is how much of the industrial value generated by these public investments actually remains within Italy’s domestic production system.

Over the medium to long term, excessive outsourcing of high-value production phases may reduce the national industry’s ability to maintain and develop technical skills, design expertise, and system integration capabilities. This is particularly relevant for small and medium-sized new builds, such as specialized vessels or ferries, where Italy’s competitive advantage lies more in value added than in cost.

Design, detailed engineering, system integration, advanced environmental solutions, and lifecycle management remain areas of consolidated Italian expertise. Strengthening these capabilities along the value chain could help capture a larger share of project value, even in an open international market.

From this perspective, the central question is not whether to involve foreign operators, but how to structure tenders and industrial strategies to foster distinctive capabilities within the national system. The challenge for the Italian maritime sector is to secure a strong position in high-technology, high-value phases, ensuring that public fleet renewal does not lead, over time, to the gradual loss of strategic know-how.